Motor : RIGHT SIDE

MAIN COLOR-WAP- 3290 GRAY

SIDE COLOR-WAP -3292 Beige

VACUUM COLOR WAP-3280 Royal blue

BASIS PARAMETER

1. Mechanical wheel width : 1700mm

2. Product's width : 1500mm

3. Mechanical speed : 3~20m/min (frequency control)

4. Total installed power:110 KW

5. Cooling method:water

6. On Purchaser's side

Auxiliary equipment :

a) oil pipe

b) air compressor(working pressure: 0.6Mpa;0.5m3 /min) pipe, cut-off valve and insulated, compressed air pipe

c) 10~15 p industrial water cooler

d) equipment installation excipients and all material for testing machine

PARTICULAR DESCRIPTION

1. Two station Sending Platform

1) Framework is welded and composed with formed steel and steel plate

2) Max sending rolling diameter : Φ1000mm

3) Automatic tracking of photoelectric counterparts 0.75KW...............................................................................1SET

4) Manual breaker...................................................................................................................................................................2SET

5) 30*30 square axis(the demensicion of axis offered by buyer)....................................................................2PIECES

6) Φ100 guide roller..........................................................................................................................................................2PIECES

2. 15 Meters storing frame

1) Framework is welded and composed with formed steel and steel plate

2) Φ100 guide roller.......................................................................................................................................................11ROLLS

3) Φ130 traction rubber roller,steel roller.......................................................................................................................1SET

4) Φ130 pressure rubber roller, steel roller mechanism...........................................................................................1SET

5) Chain and chain wheel for Lifting wheel frame.......................................................................................................1SET

6) 2.2KW transimmison reductor group..........................................................................................................................1SET

7) 1.5KW cylinder station group..................................................................................................................................1Station

3. Main heating parts

1) Framework is welded and composed with formed steel and steel plate

2) Φ100×1700 guide roller............................................................................................................................................2PIECES

3) Pre-affixed Prejoint gas cylinderQGB80*75...........................................................................................................2SETS

4) Pre-affixed silicone rollerΦ160*1700.....................................................................................................................1PIECE

5) Aluminum shelled extending roller : Φ136............................................................................................................1PIECE

6) Φ960×1700 Double-cylinder pre-heating, the surface is painted with Teflon.......................................1PIECE

7) Gear reducer and motor 2.2KW....................................................................................................................................1SET

8) DN32 heating-oil single-floating revolving joint.................................................................................................2SETS

9) Oil-heating metal tube DN32×600........................................................................................................................2PIECES

10) Oil-heating circulation system, domestic products.............................................................................................1SET

11) Electrical three-way Thermovalve DN25 (made in Taiwan)..............................................................................1SET

12) Heating cover.....................................................................................................................................................................1SET

13) Old medium-wave heating lamp 3KW/pc(LONG).......................................................................................18PIECES

14) Gold medium-wave heating lamp 1KW/pc(Short)........................................................................................6PIECES

15) Infrared temperature sensor(U.S.A brand)........................................................................................................3PIECES

16) Traction rollerΦ73×1700 , the surface is painted with Teflon....................................................................4PIECES

17) Taction roller transmmion mechanism.....................................................................................................................1SET

18) Transmmision train wheel and train mechanism..................................................................................................1SET

19) Reductor and motor for lifting 0.37KW(Made in Jiangmen)............................................................................1SET

4. Vacuum embossing group(Made in Taiwan)

1) Main machine.......................................................................................................................................................1SET

2) Aluminum bar.......................................................................................................................................................1SET

3) Rubber hose..........................................................................................................................................................1SET

4) RollerΦ 460-2300.................................................................................................................................................1SET

5) Vacuum pump 40hp including switchbox 30kw..........................................................................................1SET

6) Reductor motor, 3hp 30:1..................................................................................................................................1SET

5. Three cooling groups

1) Framework is welded and composed with formed steel and steel plate

2) Φ570 stainless steel cooling cylinder......................................................................................................................3PIECES

3) Water-use single-floating revolving joint DN25.................................................................................................6PIECES

4) Gear reducer and motor 2.2KW (nationally name-brand).....................................................................................1SET

5) Stainless guide rollerф100.............................................................................................................................................1PIECE

6) Transmission gear.................................................................................................................................................................3PCS

7) High-pressure black rubber water pipe DN25........................................................................................................6PIPES

6. Electric round-blade type trimming and traction mechanism

1) Framework is welded and composed with formed steel and steel plate

2) Trimming motor 0.37KW (nationally name-brand).................................................................................................2SETS

3) Gear transmmision equipment........................................................................................................................................2SETS

4) Up, down round blade........................................................................................................................................................2SETS

5) Sliding block and Linear guide pair...............................................................................................................................2SETS

6) Trimming width adjusting mechanism...........................................................................................................................1SET

7) Supporting cross beam....................................................................................................................................................1PIECE

8) Φ100 duralumin roller.......................................................................................................................................................1PIECE

9) Traction guide roller Φ150...............................................................................................................................................1PIECE

10) Pressure –tighten gas cylinder 80×100..................................................................................................................2PIECES

11) Pressure –tighten rubber roller Φ150........................................................................................................................1PIECE

7. Two-station center rolls taker

1) Framework is welded and composed with formed steel and steel plate

2) 40N.m torque Motor and worm reduction gear.........................................................................................................1SET

3) Φ100 duralumin roller.....................................................................................................................................................2PIECES

4) 30*30square axis(the demensicion of axis offered by buyer)..........................................................................2PIECES

5) Fast-dispatch disk................................................................................................................................................................2PAIRS

6) 1.5KW brake motor and reducer........................................................................................................................................1SET

7) Turnover worm and worm wheel pair..............................................................................................................................1SET

8) Turnover arm and spindle.....................................................................................................................................................1SET

ELECTRIC CONTROL

1. The overall transmmision speed-adjustment is controlled by transducer, whose brand is “EMERSON-CT”, and the controlling method is PLC&HMI.

2. The heating lamps of electric heating group make use of Gold medium-wave heating lamp, total 24pieces for 5 groups.All make use of tunable solid relay for control.

3. U.S.A brand infrared temperature sensor test the surface of material,also can Auto- control or hand-control the heating temperature.

4. The rewinding part adopt 40N.M moment motor for controlling.

5. Other electrical components are imported or made in Taiwan

6. Overall line equipped with one main electric tank, one main panel, one rolls box for controlling.

POWER CONFIGURATION TABLE

A. Action transmmision motor (Frequency control) 9.55KW

1) Storing frame transmission 2.2KW...................................................................................................................................1SET

2) Main heating cylinder transmission 2.2KW.................................................................................................................1SET

3) Vacuum embossing transmission 2.2 KW (Taiwan)..............................................................................................1SET

4) Three cooling groups transmission 2.2KW.................................................................................................................1SET

5) Traction transmission 0.75KW..........................................................................................................................................1SET

B. Not-main transmission motor 40.36KW

1) Edge elignment equipment 0.75KW..............................................................................................................................1SET

2) Heating cover lifting 0.37KW............................................................................................................................................1SET

3) Storing frame cylinder station 1.5KW............................................................................................................................1SET

4) Edge trimmer 0.37KW×2=0.74KW.................................................................................................................................2SET

5) Reverse motor 1.5KW..........................................................................................................................................................1SET

6) Moment motor 5.5 KW......................................................................................................................................................1SET

7) Water circle type vacuum pump 30 KW.........................................................................................................................1SET

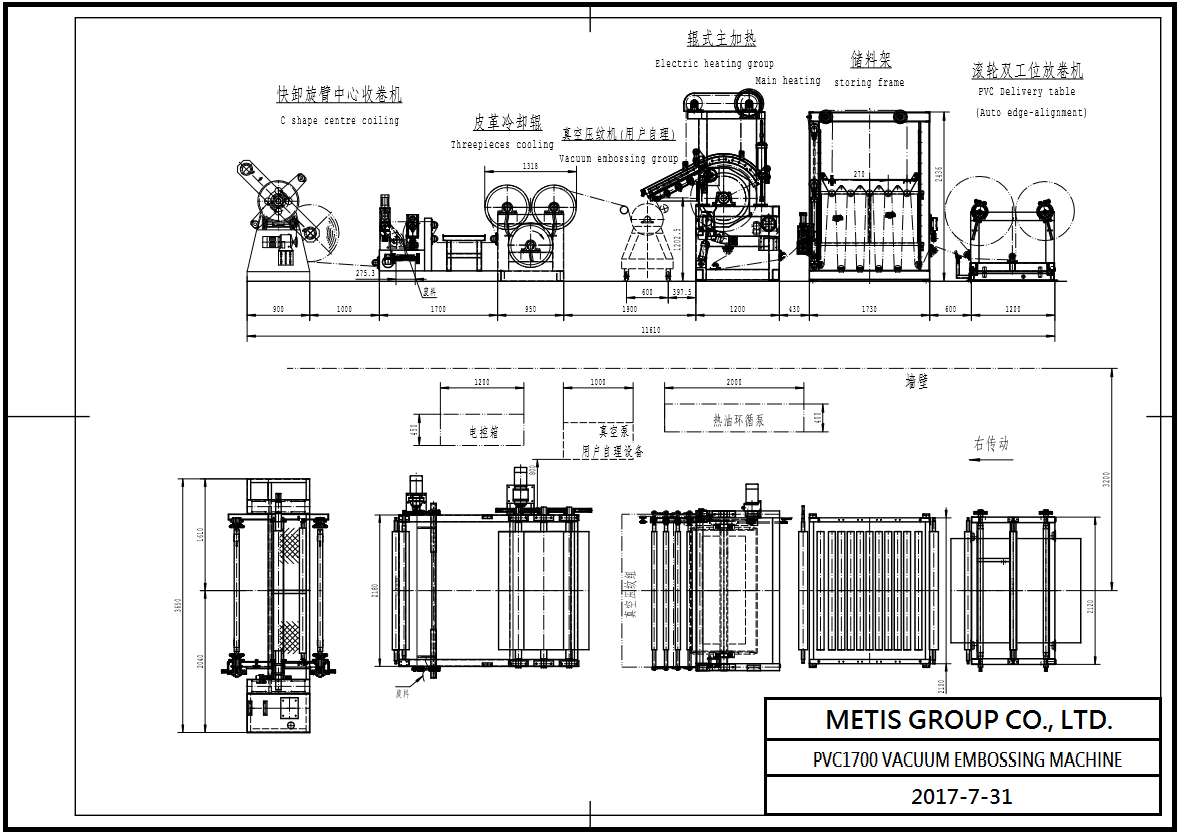

MACHINE DRAWING